Chilled Water Pump Vfd Control

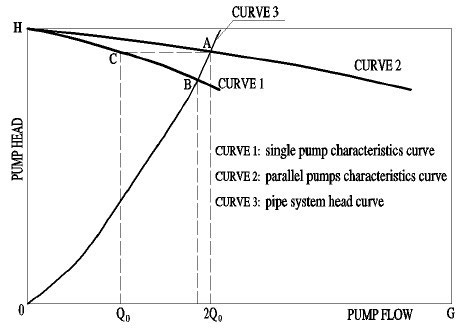

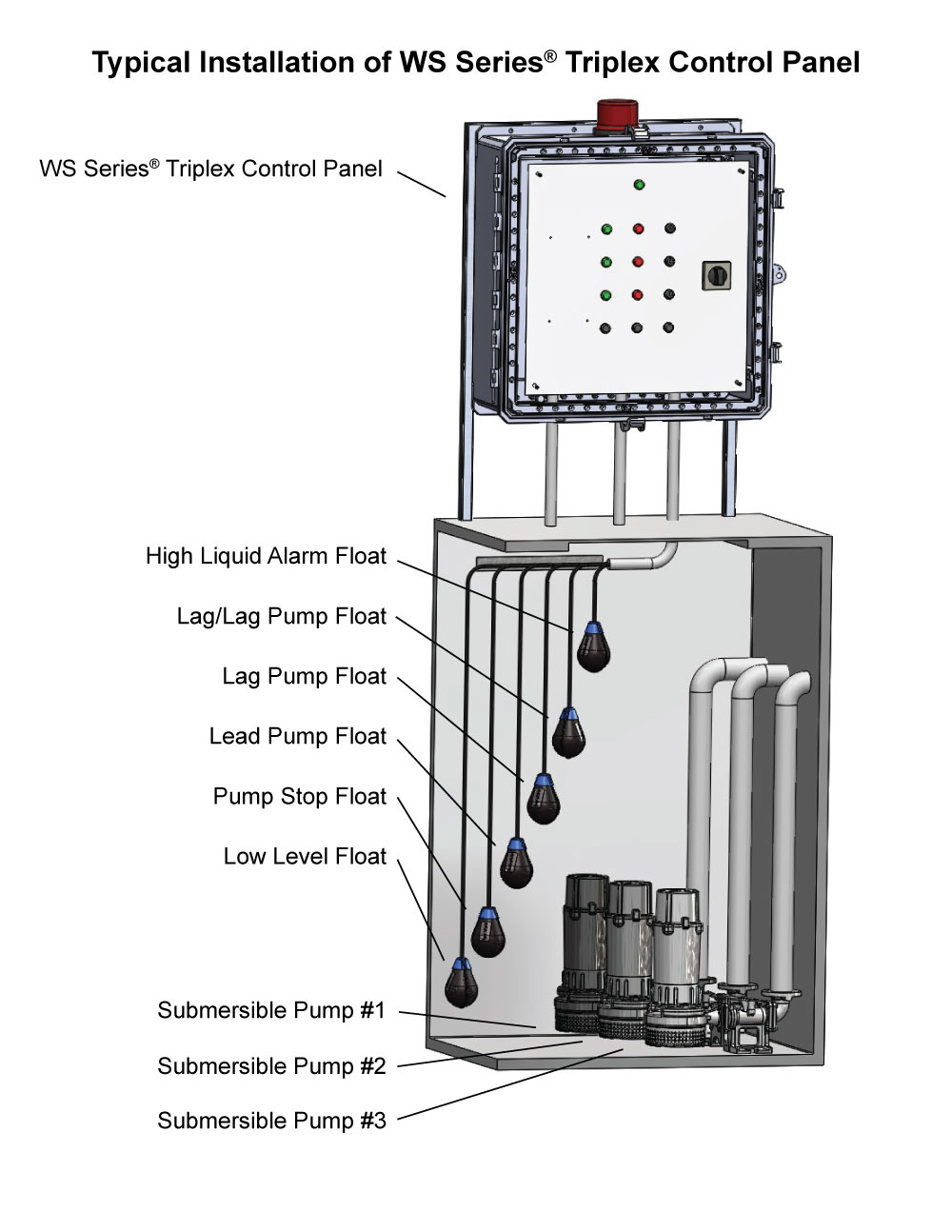

The pumps are designed to operate in a parallel configuration.

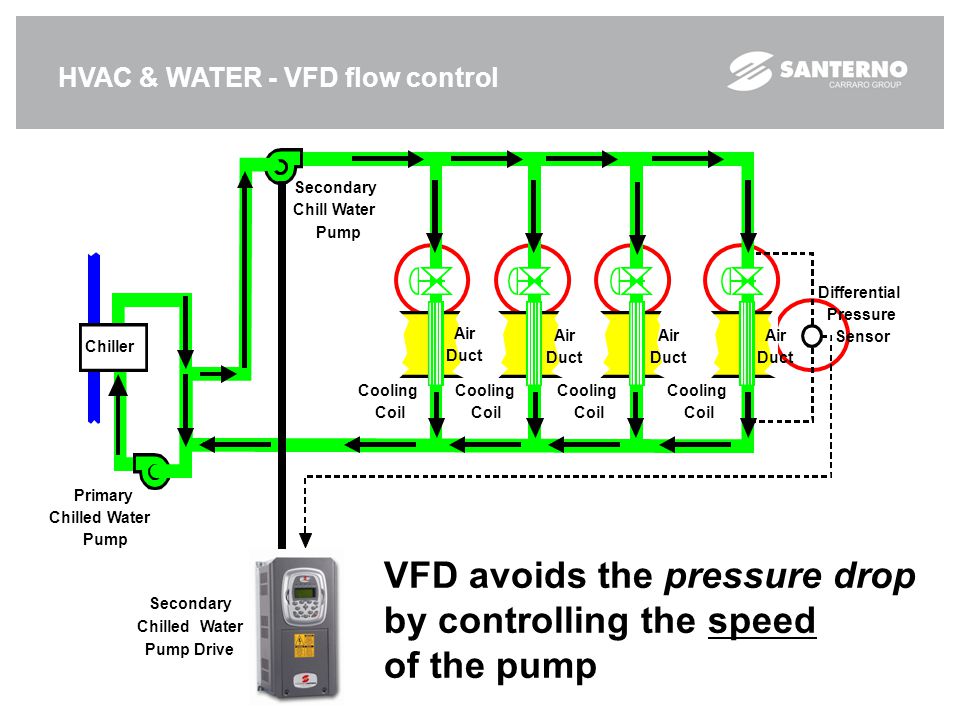

Chilled water pump vfd control. As the chilled water valve begins to open the chilled water differential pressure transmitter senses a drop in system pressure. The purpose of the vfd installed on secondary chilled water pump motor is to increase or decrease the speed of motor in order to control increase or decrease water flow rate. Before variable speed drive vsd and direct digital control ddc techniques existed the chilled water pump delivered the chilled water to distribution loops at the constant flow rate regardless of the variation of. Enable both primary and secondary chilled water pumps when outside air temperature is above setpoint and at least 1 chilled water coil control valve is open to coil.

Modulate vary the speed of the secondary pump vfd to maintain a constant differential pressure. This is an indication that the plant pressure is no longer sufficient to satisfy the building chilled water demand. Secondary pump in chilled water system is responsible to pump the chilled water to load end i e. This increase or decrese in motor speed and accodingly flow rate is governed by means of pressure sensors pressure transducers.

The control technology of vfd is closely related to characteristics of pumps. Enable chiller after flow is proven. Currently a single pump is operating in response to water flow requirements. The secondary chilled water pump schwp sets will be controlled through vfd drives to maintain the desired system differential pressure.

Calculated setpoint for more than 15 minutes adj close the bypass valve open the main building return control valve to 100 and enable the pump control sequence. The main goal of the secondary chilled water system is to distribute the correct amount of water to satisfy the load. This sends a signal to the chilled water control panel and vfds. Vfd s variable frequency drives are usually employed to serve the purpose of feeding electrical power to pump motors as these provide a good control over speed of motor which in turn changes the gpm s gallon per minutes being supplied to load end.

Based on the mathematical a model of pumps with or without variable frequency drives the paper discusses some issues in detail such as variable frequency drives configuration flow rate regulation and overload. It must first accurately monitor the system for changes in load dynamics.